Introducing Q.tool epoxy prepreg tooling technology

Groundbreaking new tooling prepreg system designed, developed and manufactured by PRF.

Q.tool (UK Patent GB2614600) significantly reduces the time and costs of tool manufacture, with its uniquely designed surface and 1020 bulk plies.

Using our class-leading RP800 epoxy tooling system, the combination of Q.tool’s new surface and 1020g/m2 bulk plies provides the same weight and thickness as the 1:8:1 system, and significantly reduces the number of debulks to as few as one.

Q.tool offers the constructor:

- Up to 50% reduction in labour time

- Reduced number of debulks

- Improved sustainability and cost savings with reduced use of plastic consumables

- Exceptional drapeability and surface finish

Robert Burnell, CEO comments:

“After over 40 years in the industry, I have not seen a tooling system that provides the same benefits to the constructor as Q.tool. We have developed this innovative system to not only be a more cost-effective tooling solution, but to also provide an unrivalled surface finish due to its unique design. We are developing all of our prepreg systems with sustainability in mind, with this system working to dramatically reduce consumable plastic when processed.”

Improved Sustainability

With its unique construction, our new Q.tool prepreg tooling technology has been designed to reduce labour time by up to 50%, which contributes to a reduction of energy used in the laminating space as well. As we have also reduced the debulk requirements to as few as one, we have additionally reduced the energy per tool and this also reduces the use the use of plastic consumables to a minimum – we estimate that for each square meters of tooling, Q.tool saves at least 1sqm of breather, bagging and release film and c. 4m of tacky tape at least per tool per debulk. More consumables can be saved with large/complex mouldings.

Review our recent presentation at Composites UK's Tooling for Composites Showcase

Q.tool News:

November 2023: UK Patent granted for Q.tool Prepreg Tooling Technology.

A year and a half after the launch of this groundbreaking product, we are delighted to announce that the company has been granted a UK patent (Patent GB2614600) on Q.tool Prepreg Tooling Technology. The UK Intellectual Property Office has issued the patent grant for the prepreg’s unique design, confirming Q.tool is an original, distinct and innovative technology in tooling prepreg. Read the full press release here.

October 2022: Q.tool selected as part of the Innovation Gallery at Advanced Engineering

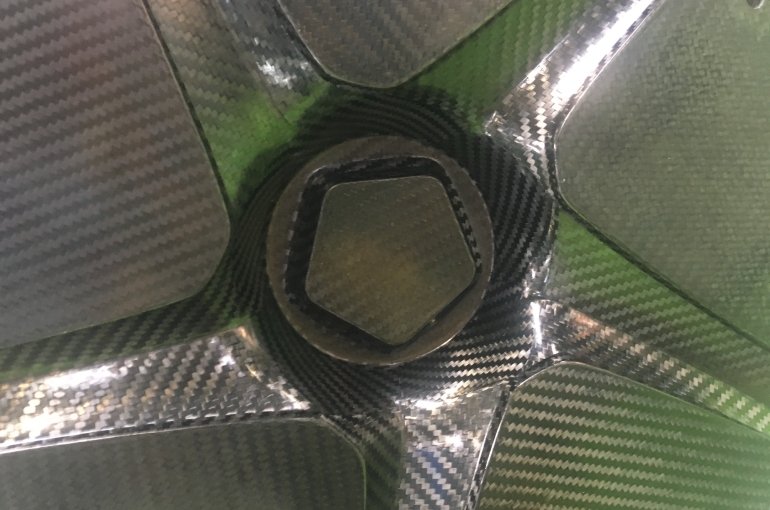

The two carbon mould tools on display were constructed by Supernatural-x using our Q.tool tooling technology. Compared to using the conventional 1:8:1 season with RP800, Supernatural-x has confirmed a time saving on labour of 51%. The surface finish is exceptional and you can see the component (motorsport seat application) that was constructed using these carbon moulds on PRF's stand (V150).