From our very foundation, PRF has offered an industry-leading service to marine manufacturers. Our knowledge and materials have been utilised by manufacturers of large yachts, rowing skulls, racing dinghies, powerboats and by the canoeing/ kayaking industry, including paddle shaft manufacture. We have also supplied materials into ocean racing yachts sailed in the America’s Cup and rowing skulls in previous Olympic gold medal-winning 8s and pairs categories.

In 2022, PRF was announced as material suppliers to the ThrustWSH project, a project led by Richard Noble OBE and Lorne Campbell to break the water speed record. You can read more about ThrustWSH and PRF's involvement here, and follow the latest news on thrustwsh.com. You can also follow PRF on LinkedIn for regular updates.

Talk to our team about your application today.

"We are all really happy with the result, brilliant clarity with the weave pattern and very uniform."

John Feay, Composite Engineering Manager, Jeremy Rogers Limited

Prepreg

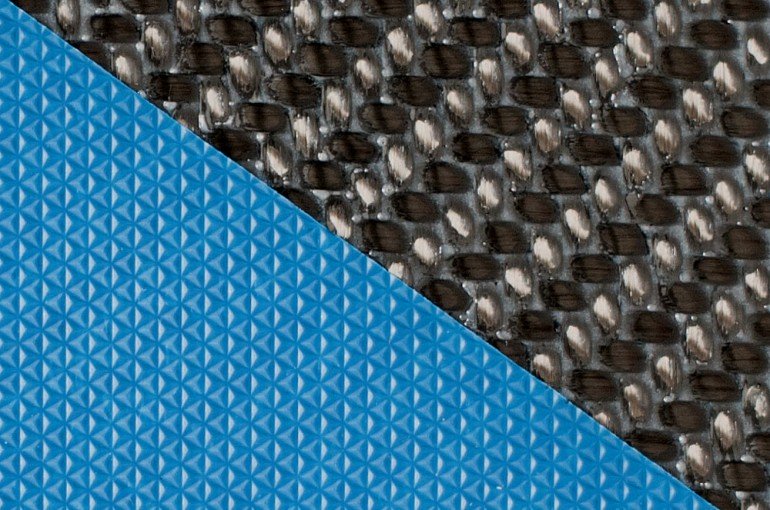

With 40 years' experience of working with advanced technical textiles, PRF specialises in visual quality component prepregs and specialist hybrids for bespoke applications. Our team produces exceptional visual quality prepreg materials, which are already used by leading brands for high end aesthetic components. Our RP542-1 and RP542-4 systems provide an aesthetic quality finish in the component, with RP542-4 available in UD carbon and glass as well as our wide range of woven fabrics. We have also developed a full range of tooling prepregs, including an overnight cure system with an out life of 12 days at 20°C - particularly suited to creating large scale tools - as well as our highly toughened RP549 system and our snap cure system RP570.

Epoxy Resin Systems

We have a class-leading and extensive range of epoxy resin systems, varying from low viscosity systems for room temperature laminating, RTM and resin infusion to systems with high operating temperatures, specialist gelcoat formulations and adhesives. Where possible, the precursors used in the formulation of our resin systems are carefully selected to reduce odour levels and to provide good physiological properties, minimising skin irritation and skin allergy problems. For optimum processing flexibility our resin systems also come with a range of hardeners which vary in reactivity.

Reinforcements

PRF develops and supplies a range of narrow width woven tapes and both flat and tubular braids. Typically used as local reinforcement, our flat woven tapes are available with powder coating for RTM applications and our uni-directional reinforcements can be woven in tubular form with elasticated weft fibres. Our flat and tubular braids are manufactured in a variety of diameters and in virtually any fibre type. For these products, and a number of our other fabrics, we offer laminating and slitting services.

Our braided reinforcements have unique properties which make them suitable for complete part manufacture or local reinforcement in applications where fibres need to be oriented at angles rather than at 0°/90°, as found in woven fabrics. Braids are especially functional in applications where high shear loads can be expected; for instance, for joining components. The exceptional drapeability of these materials make them highly suitable to provide reinforcement over complex contours. We offer biaxial, triaxial and elasticated flat braids and tubular braids and braided preforms. Most fabrics are available.

Multiaxial fabrics, which are ideal for heavyweight components where the high weight of the fabrics, together with the ability to orientate the fibre at different angles, enables fewer layers to be used. PRF stocks a range of high-quality multiaxial fabrics including:

Carbon multiaxial in 0/90°, +/- 45°, Triaxial and Quadraxial configurations, in weights from 150gm/m² to 500gm/m²

E-Glass multiaxial in 0/90°, +/- 45°, Triaxial and Quadraxial configurations, in weights from 300gm/m² to 1200gm/m²

Other fabrics are available, including Kevlar® multiaxial fabrics.

Qiicote Mould Release Technology

To complement our range of advanced composite products, PRF developed Qiicote mould release technologies for thermoset and thermoplastic composites. The Qiicote range of products offers hard-wearing release films giving multiple releases with no contaminating transfer; parts can be finished with paint systems outside the mould without further preparation. The range includes cleaners, sealers and semi-permanent release agents. The benefits of using these products include variable slip with a high gloss finish, a number of ways to apply, no contaminating transfer from mould surface, low cost per part released and a maximum release performance.