The motorsport industry has always been an early adopter of advanced technology. Motivated by the desire to decrease weight and increase component strength, Formula 1, Rally and Touring cars have utilised lighter and stiffer materials for decades; PRF was amongst the first suppliers of Formula 1 and Indi car manufacturing. Over 40 years later, PRF still works with leading motorsport constructors, as well as first-class road production vehicles.

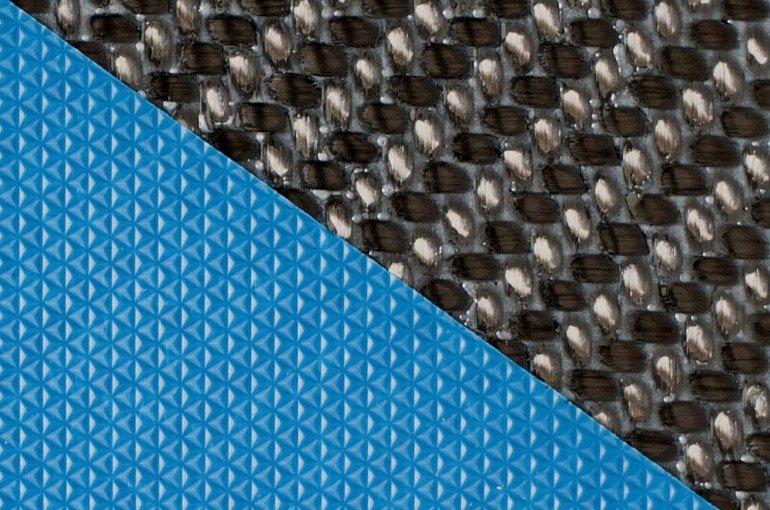

Our class-leading, innovative prepreg range includes highly toughened, snap cure, tooling, visual quality systems and more, and is combined with our 40 years’ experience working with technical textiles. We also offer a vast range of dry reinforcements and epoxy resin systems for wet lay-up and infusion processing.

Talk to our team about your material requirements today.

Prepreg

PRF manufacturers a class-leading range of tooling and component prepreg systems that can be tailored to suite our customers’ particular requirements. Of particular interest to motorsport and automotive constructors are our highly toughened RP549 system - which has excellent mechanical properties, our RP570 eXpress cure system for pressed components in 4 minutes, and our range of tooling systems. We have also recently launched our fire-retardant RP570 FR eXpress cure, which can produce pressed component with FST properties in 5 minutes at 160°C. Our significant experience developing specialist materials means that we can develop a number of prepreg and resin-based systems designed specifically for the end application.

Our tooling prepreg range is market-leading, including our groundbreaking Q.tool prepreg tooling technology which significantly reduces the time and costs of tool manufacture. Using our class-leading RP800 epoxy tooling system, the unique combination of Q.tool’s new surface and 1020g/m² bulk plies provides the same weight and thickness as the 1:8:1 system, and significantly reduces the number of debulks to as few as one.

We also hold a large stock prepreg in our cold storage facility for overnight delivery.

Kit Cutting

Our highly efficient and cost-effective composite kit cutting service provides consistently cut, high-quality kits with reduced labour time and cost. We can cut most commercially available prepreg and dry fabrics, and nest for optimum material usages. Kits are supplied kits bagged, labelled and ready for immediate use.

Reinforcements

We have extensive experience in developing bespoke woven and non-woven fabrics and will work together with clients in order to design the ideal solution to suit the requirements. Such bespoke materials can include new hybrid wovens, new weave patterns or new wovens using speciality fibres and materials. We can start this bespoke service with an order of just 7m for sampling and testing. We also provide materials for cosmetic applications, including aesthetic grade carbon fibre which is woven to the highest standards.

In addition, PRF supplies a vast range of narrow tapes and braids, including state-of-the-art spiral woven tapes and spiral braids and 3D woven profile structures for preforms, where fibres are woven in a 0/90° orientation and also in 3D, right-angled on warp and weft; providing x, y & z axis reinforcement in the component. These innovative materials provide a number of exciting possibilities in motorsport and automotive applications.

Epoxy Resin Systems

PRF provide a class-leading range of epoxy resin systems which contains a variety of systems, varying from low viscosity systems for room temperature laminating, RTM and resin infusion to systems that operate in high temperatures, specialist gelcoat formulations and adhesives. New additions to our range include RTM resin systems with short cycle times; these are of particular interest to the automotive and motorsport industries, where production time is critical.

Qiicote Mould Release Technology

To complement our range of advanced composite products, PRF developed Qiicote Mould Release Technologies for thermoset and thermoplastic composites. The Qiicote range of products offers hard-wearing release films giving multiple releases with no contaminating transfer; the range includes cleaners, sealers and semi-permanent release agents. The benefits of using these products include variable slip with a high gloss finish, a number of ways to apply, no contaminating transfer from mould surface, low cost per part released and a maximum release performance.