Market leaders in quality and innovation

At PRF, we are passionate about product development, with an emphasis on helping customers reduce manufacturing time, and improve efficiency and cost-effectiveness. Building on 40 years’ experience developing and working with advanced reinforcements, our team brings this knowledge and understanding to our prepreg manufacturing; incorporating high quality fabrics in a variety of fibre types, constructions and fabric technologies. We combine this with in-house resin system development focussed on offering customers improved solutions for manufacturing.

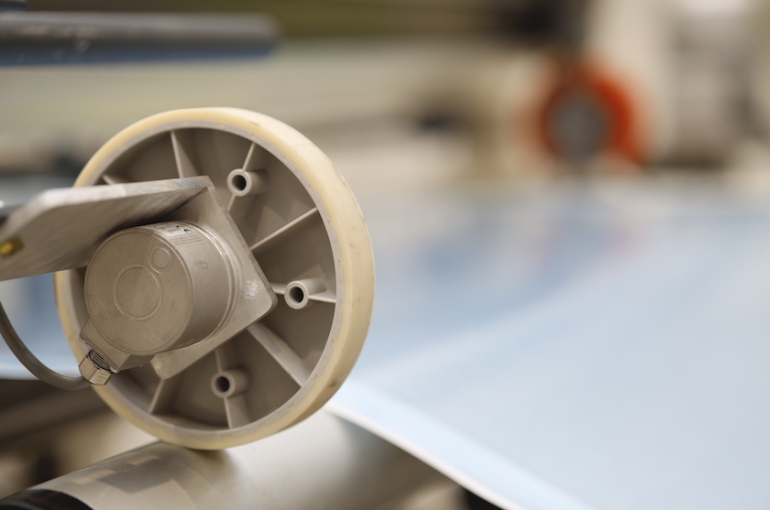

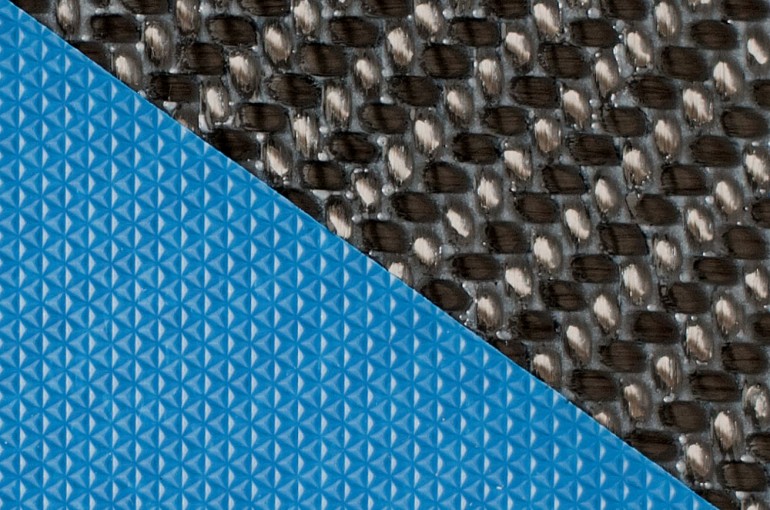

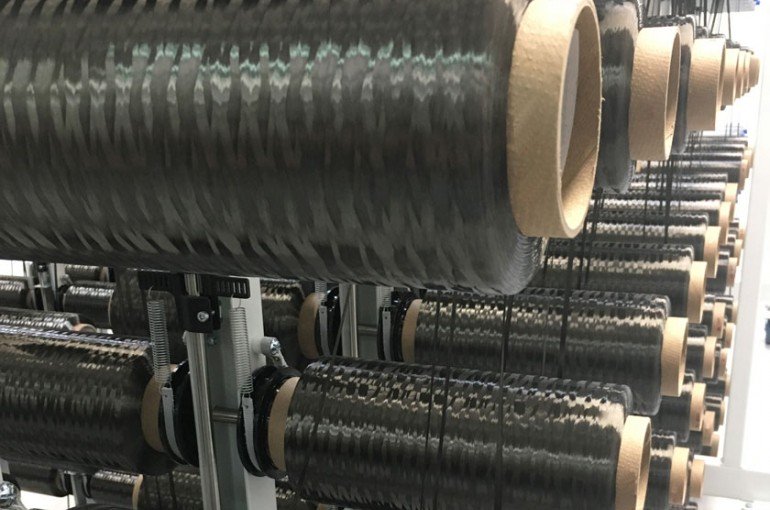

Our manufacturing capabilities include both solvent dip and hot melt processes with a range of materials, including fabrics such as woven carbon fibre, glass fibre, aramid fibre, hybrids, unidirectional carbon and glass fibres, as well as visual quality fabrics and prepregs with carbon nanotube additives. In addition, we supply resin films and adhesive films. Our hot melt line, which has a capacity of over 1 million square metres p.a. at up to 1.5m wide, is supported by chemists, engineers and technicians with extensive lab facilities, and incorporates the latest film weight scanning technology, in-house resin system development and R&D. To support our manufacturing and product development, we have a process laboratory and a material testing laboratory, where we perform mechanical testing (bending, tensile, shear and peel off) to ISO and ASTM standards, as well as rheology, DMA and DSC. We manufacture a wide a wide range of innovative component and tooling systems, and concentrate our product development on innovative products that will save our customers time and money and provide outstanding results in tools and components.

In 2019 we installed our state-of-the-art unidirectional prepreg line and are now able to produce unidirectional carbon prepreg in 300 g/m² and 600 g/m² and unidirectional glass prepreg in 400 g/m².

As with our other products, we are able to work with speciality and bespoke materials, and can accommodate smaller runs of 50m for such applications. We also have experience of working with speciality materials such as Dyneema®, metal and metal-coated fibres, and Quartz. Working from the original PRF philosophy, we believe that standard prepreg materials should be on stock, ready to suit our customers’ manufacturing, not our own. As such, we stock large quantities of our standard lines in our purpose-built 360m3 freezer, ready for rapid delivery.

Providing a full service, we are also able to cut a wide variety of prepreg at our kitting and preforming centre; supplying kits bagged and ready for use.

To support our manufacturing, we also have an established kit cutting service, for our prepreg and dry materials and comprehensive R&D and testing facilities.