PRF has significant experience in providing prepreg and dry kits to customers in aerospace, marine, renewable energy, motorsport and more.

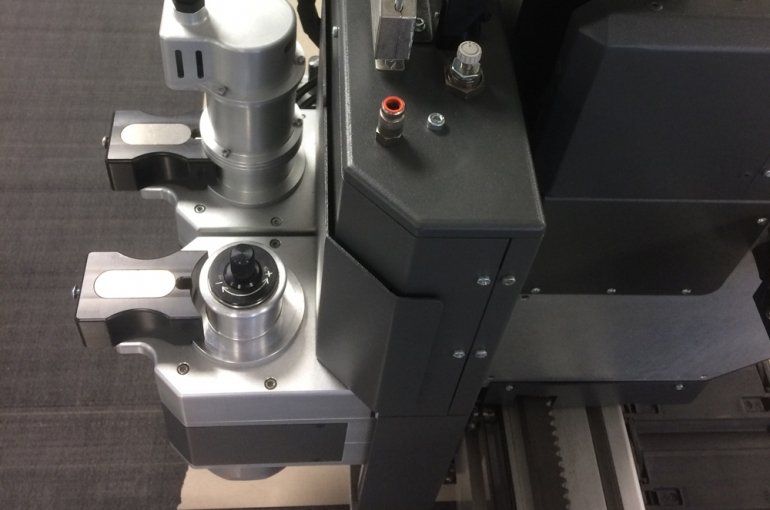

- 14,700sq. ft purpose built kitting centre, equipped with 4 conveyerised CNC cutters, cutting dry and prepreg materials, supported by a dedicated CAD office

- Approx. 100,000 sqm of material per year converted into kits

- Supplying 8 Industries across 12 countries

We use static, rotary and oscillating blades and have a great deal of experience achieving high quality, consistent results with the more difficult technical textiles; we can cut Dyneema® and Kevlar®, including ballistics grade Kevlar® up to 25mm thick.

Waste management

We nest for optimum material usage and can supply materials in kits, assembled to our customers’ requirements; saving your time and labour costs.

We take care of and - as far as possible - recycle the waste. We send approx. 1800kg of glass off cuts to recycling projects per year and, this year, we will be sending carbon kitting waste to be recycled into carbon chopped mat to make our recycled REEPREG prepreg material.

Optimisation

We can include out-life sheets, lot traceability, labelling and more as required. Prepreg kits can be stored in our freezer facility, ready for immediate dispatch and ‘just-in-time’ delivery service. As kits are packed flat, we optimise shipping and storage at your facility as well - not only saving costs but also providing sustainability gains as well.

Talk to our team today about our kit cutting service.