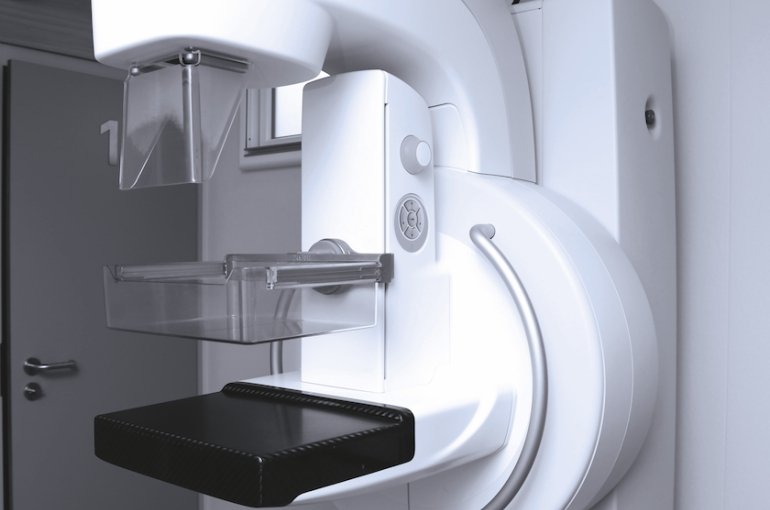

Composites in medicine range from the large scale components, such as those used for x-ray – including mammogram – applications, to the almost invisible: composite bolts used internally to support bones.

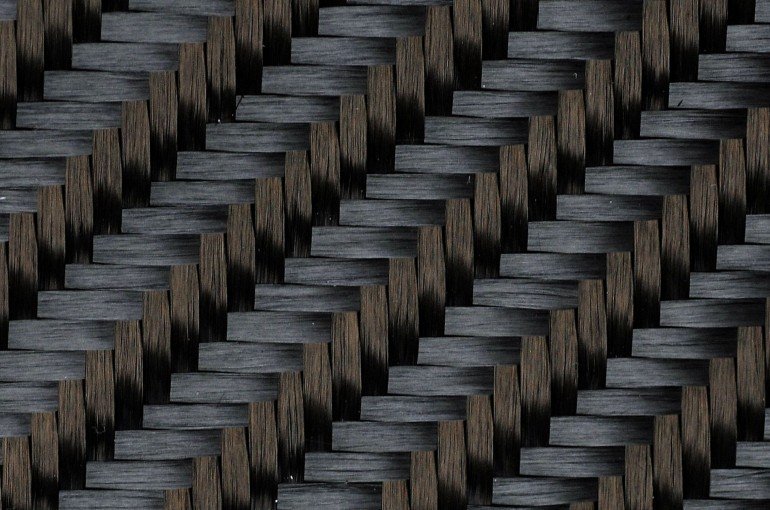

PRF have proven prepregs, reinforcements and epoxy resin systems currently used in the medical industry. Our carbon prepreg, with specific matrix, maintains the transparent properties necessary for x-ray applications but retains all the mechanical benefits that carbon fibre has to offer. We are also a long-standing supplier to the prosthesis and orthotic industry, both with our prepreg materials and with our high quality range of woven and braided tubulars, and our state-of-the-art spirally woven tapes and spiral braids.

Talk to our team about your material requirements today.

Prepreg

PRF provides and innovative and responsive prepreg system, allowing us to use more specialist materials and provide prepreg systems that are tailored to suit our customers’ niche requirements. Our significant experience developing specialist materials means that we can develop a number of prepreg and resin-based systems specifically for medical applications such as x-ray equipment, where the matrix must not compromise the transparency of the carbon fibre itself.

Following the opening of our third facility, we have continued expansion by increasing onsite UD prepreg manufacturing. PRF’s state-of-the-art line has been installed at our head office and prepreg manufacturing facility, and is supported by R&D chemists, with in house resin system development – making these new materials fully compatible with our range of woven prepregs – and extensive lab facilities equipped for mechanical testing, rheology, DMA and DSC.

Our new UD prepreg capability includes carbon materials from 80 to 600gsm, at standard widths of 300 mm and 600 mm. Other widths are possible, if required.

Epoxy Resin Systems

Our class-leading range of epoxy resin systems is used extensively throughout the wind energy industry. Our comprehensive range contains a variety of systems, varying from low viscosity systems for room temperature laminating, RTM and resin infusion to systems that operate in high temperatures, specialist gelcoat formulations and adhesives. Our vast range allows us to supply the most suitable resin for the application, to cater for niche technical requirements or processing capabilities.

Reinforcements

We have extensive experience in developing bespoke woven and non-woven fabrics and will work together with clients in order to design the ideal solution to suit the requirements. Such bespoke materials can include new hybrid wovens, new weave patterns or new wovens using speciality fibres and materials. We can start this bespoke service with an order of just 7m for sampling and testing. We also provide materials for cosmetic applications, including aesthetic grade carbon fibre, extra high quality, fault free fabric, which is woven to the highest standards.

Our range of narrow woven tapes for composite reinforcement complement our range of broad loom products and are available in widths from 10mm – 350mm wide, from carbon, aramid (Kevlar®), glass and polyester fibres. Uni-directional tubular reinforcements can also be woven with elasticated weft fibres, providing quality materials for the construction of realistic artificial limbs. We also supply state-of-the-art spiral woven tapes and braids. These unique products enable you to lay a unidirectional reinforcement around circular shapes, mould or penetration. These materials provide a number of exciting opportunities, particularly in applications such as exoskeleton constructions for limbs.

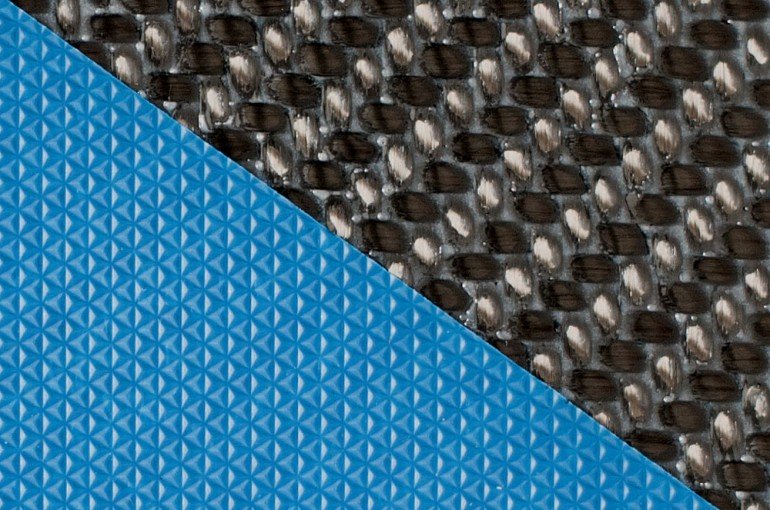

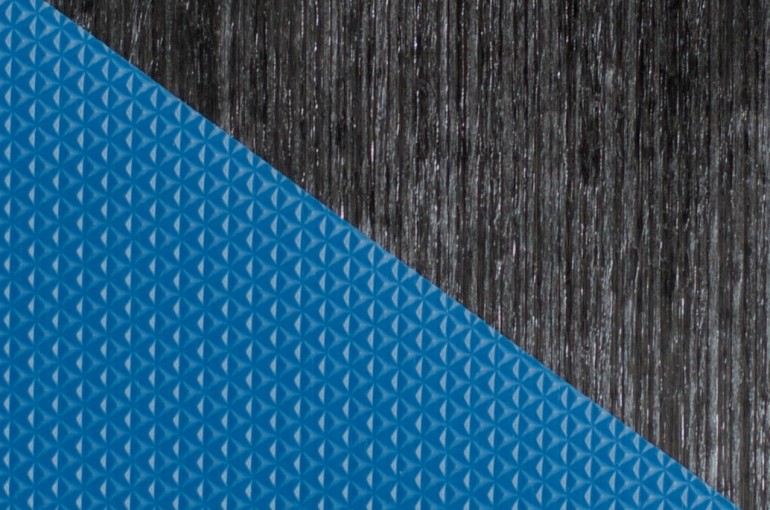

Qiicote Mould Release Technology

To complement our range of advanced composite products, PRF developed Qiicote mould release technologies for thermoset and thermoplastic composites. The Qiicote range of products offers hard-wearing release films giving multiple releases with no contaminating transfer; the range includes cleaners, sealers and semi-permanent release agents. The benefits of using these products include variable slip with a high gloss finish, a number of ways to apply, no contaminating transfer from mould surface, low cost per part released and a maximum release performance. We have also developed an internal mould release agent, water-based semi-permanent release agents, and Silicone Shield, which is a modified PVA which preserves silicone bags and seals up to 100°C.