For over 20 years, PRF have been supporting the aerospace industry with our expertise and extensive range of composite materials.

We have delivered cutting-edge, high performance aerospace composites to this fast-moving industry, providing materials that ensure decreased weight, improved fuel efficiency and trusted components. Working with our customers, we have developed products for aerospace applications, such as our new RP570 FR eXpress cure.

Formulated for structural components requiring FST properties, RP570 FR eXpress cure is a fire-retardant snap cure prepreg system, tested to Federal Aviation Requirements 25.853, AITM 2.0007 and 3.0005, UL94 V1 and FMVS Standard No.302 and currently being used in commercial aircraft interiors.

Talk to our team about your material requirements today.

Prepreg and Reinforcements

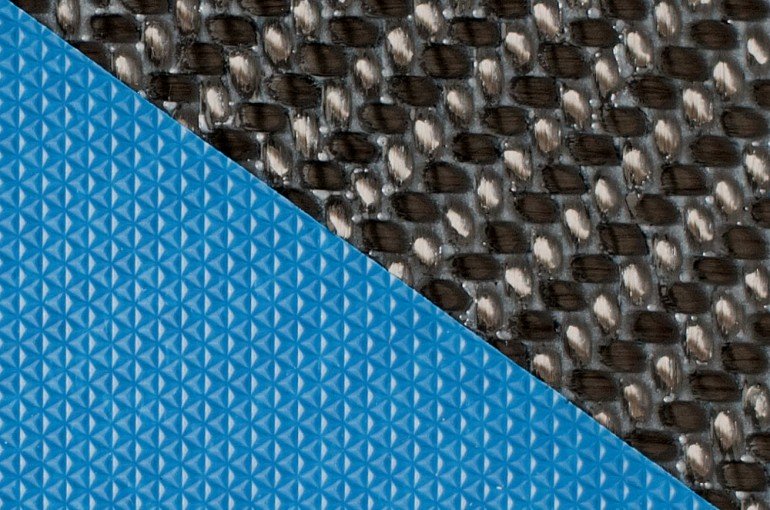

Aerospace applications often require specialist considerations. We supply prepreg and dry fabrics of aerospace grades, and we have extensive experience in developing bespoke woven and non-woven fabrics and will work together with clients in order to design the ideal solution to suit the requirements. Such bespoke materials can also fulfil specialist requirements such as lightning strike protection, EMI and RFI shielding. We can start this bespoke service with an order of just 7m for sampling and testing.

In addition, PRF supplies a vast range of narrow tapes and braids, including state-of-the-art curved woven fabrics, ideal for reinforcement around a circular shape with widths up to ~3m and diameters up to 6m. We also supply 3D woven profile structures for preforms, where fibres are woven in a 0/90° orientation and also in 3D, right-angled on the warp and weft; thus providing x, y & z axis reinforcement in the component. These innovative materials provide a number of exciting possibilities in aerospace applications.

Epoxy Resin Systems

PRF provide a class-leading range of epoxy resin systems which are approved for light aircraft and gliders. Our range contains a variety of systems, varying from low viscosity systems for room temperature laminating, RTM and resin infusion to systems that operate in high temperatures, specialist gelcoat formulations and adhesives.

Kit Cutting

Our four CNC cutting machines cut most commercially available materials in dry or prepreg form, including multiple layers of ballistic grade Kevlar®. Supplying our material in kit form saves your time and labour costs, with materials bagged, labelled and ready for use. It also provides consistent, high quality parts and lot traceability.

Qiicote Mould Release Technology

To complement our range of advanced composite products, PRF developed Qiicote mould release technologies for thermoset and thermoplastic composites. The Qiicote range of products offers hard-wearing release films giving multiple releases with no contaminating transfer; including release agents which will work with materials such as PEEK, processing at 400°C. The range includes cleaners, sealers and semi-permanent release agents. We have also developed an internal mould release agent, water-based semi-permanent release agents, and Silicone Shield, which is a modified PVA which preserves silicone bags and seals up to 100°C.